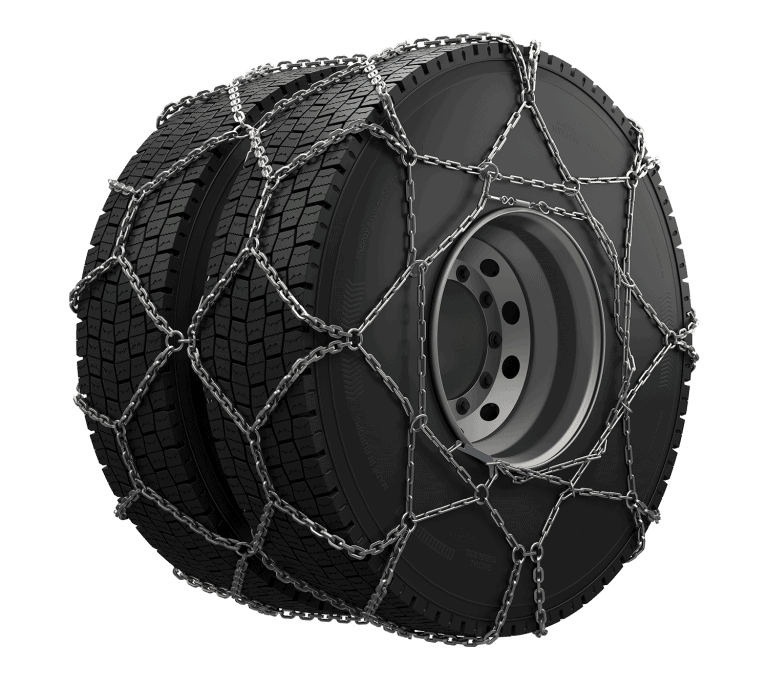

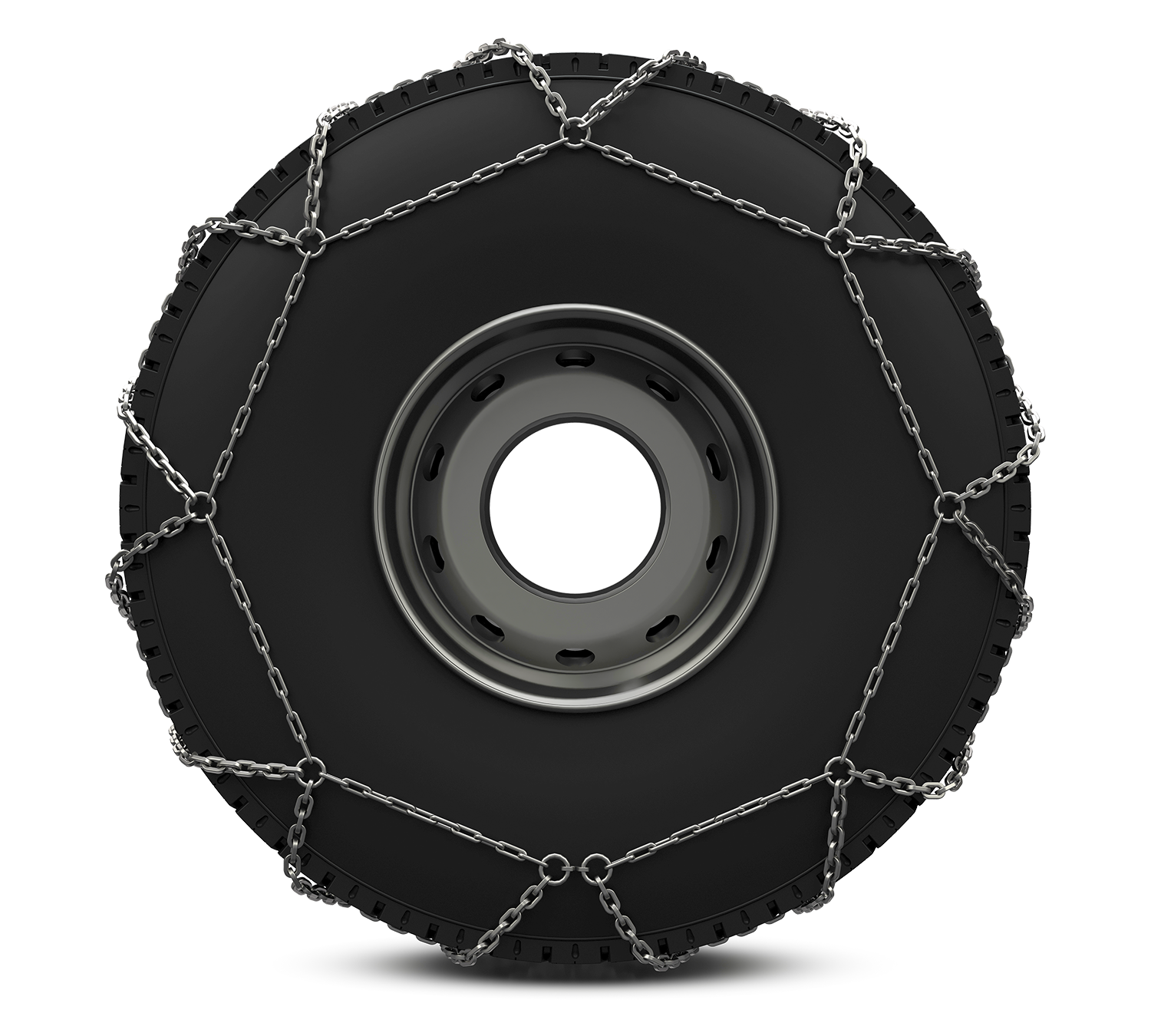

The König Rallye Pro D is the most classical snow chain for twin tyre packages used on heavy trucks.

The product design is based on two separate cross-section patterns, one for each tyre, plus the internal chain, external chain and a specific tightening chain laying between the two cross-section patterns.

The König Rallye Pro D is a supplementary grip device certified according to Ö-Norm V5119 thus fulfilling any winter equipment legal requirement for heavy vehicles.

The product is built following the traditional Professional snow chains construction, meaning that the chain is 100% manufactured in Steel, lacking of any plastic component, cable arch or anything else. Just superior quality steel and the most advanced treatments, plain and simple.

1 of 5The tensioning of the chain is given by the coupling of the tensioning lever and the tightening chain. Once reached the correct tensioning, the lever gets secured with a dedicated anti-return ring or shackle

2 of 5The outer hook is the connection point of the outer side of the chain.

3 of 5Welded side rings are the most heavy duty side connections available for snow chains involved into demanding Professional activities. The rings are welded in place and, after that, the complete snow chain is subject to a case-hardening process which ensures that not only cross-sections are treated but also all the side elements, both on the internal and on the external side.

4 of 5The tightening chain gets secured to the side chain through an elastic end composed by an heavy duty spring and a carabiner for the quickest mounting/demounting process

5 of 5

The cross-section design is generated starting from single diamonds in sequence. This is most typical cross-section design for offroad, truck and bus applications.

1 of 4Horizontal links alternated with vertical links: this is what the simple link configuration is about.

Vertical links are the ones more aggressive versus the ground while horizontal links act mainly as conjunction between the vertical ones.

The simple link technology is the most gentle versus the ground, it generates a limited vibration level and it’s the lighest available.

2 of 4The product features a middle chain meant for connecting the two chain treads and for fine tuning the positioning the single chains on the tyre treads.

The chain features an ending hook which gets secured to a ring during mounting procedure

3 of 4The middle chain shortening hooks are connecting the two single chain treads and the middle chain. The tensioning level of the middle chain influences of the shortening hooks position on the inner tyre sidewalls.

4 of 4

Welded side rings are the most heavy duty side connections for snow chains involved into demanding Professional activities. The rings are welded in place and, after that, the complete snow chain is subject to a case-hardening process which ensures that not only cross-sections are treated but also all the side elements, both on the internal and on the external side.

1 of 2The inner hook is the connection point of the inner side of the chain.

2 of 2