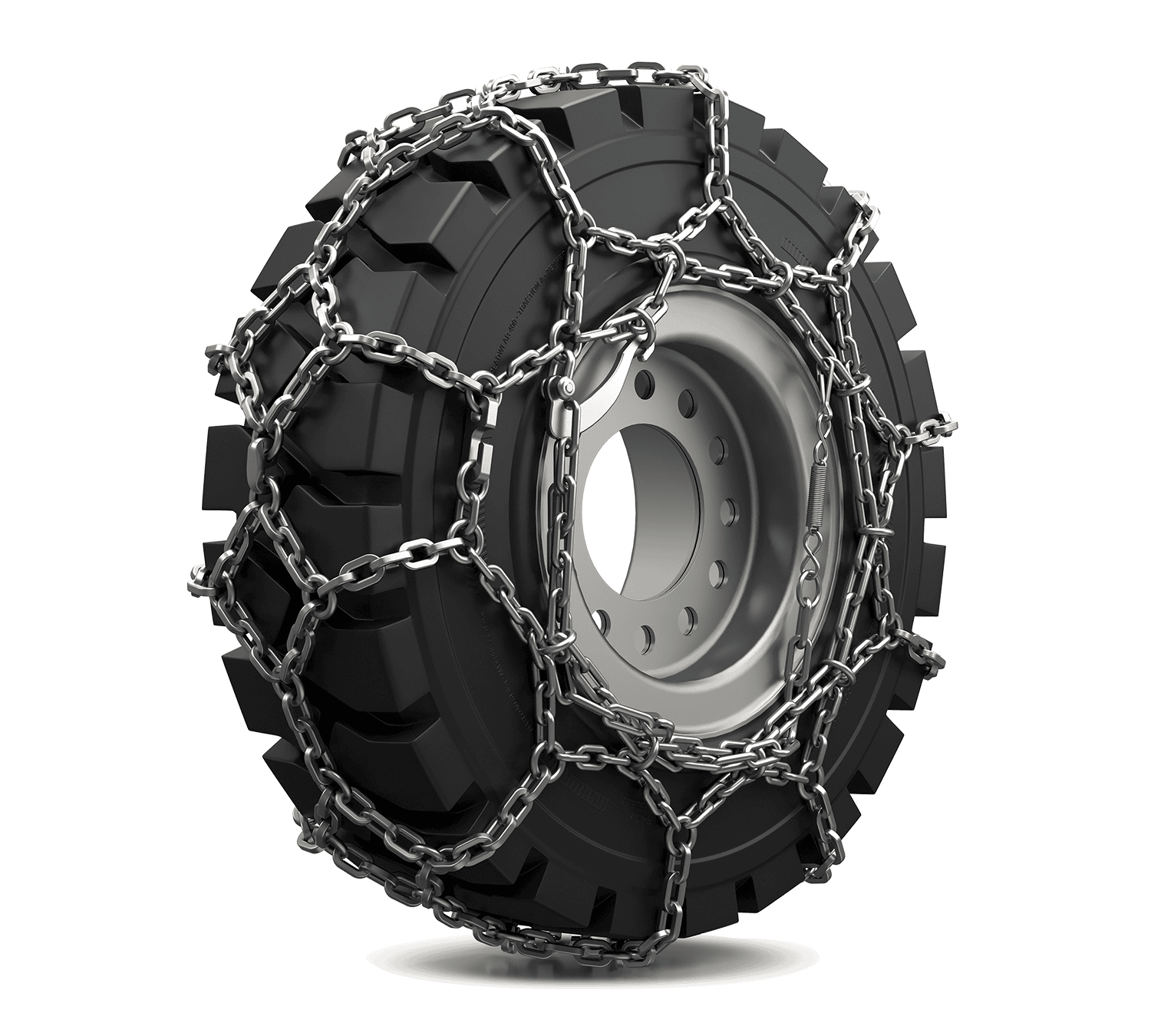

The König Load Master is the classic example confirming in the small barrel there is good wine, suggesting not to mislead the size of the chain with its strenght.

Forklifts are compact machines but responsible in carrying out some of the heaviest duty in carrying incredibly high loads during material handling operations. A better designed snow chain needs to follow the same philosophy and the König Load Master is no exception.

Being the product destined to forklifts, not beloning to M2, N2 or O2 classes, the König Load Master is not part of the application field of the Ö-Norm V5117 or V5119.

The product is built following the traditional Professional snow chains construction, meaning that the chain is 100% manufactured in Steel, lacking of any plastic component, cable arch or anything else. Just superior quality steel and the most advanced treatments, plain and simple.

1 of 5Welded side rings are the most heavy duty side connections for snow chains involved into demanding Professional activities. The rings are welded in place and, after that, the complete snow chain is subject to a case-hardening process which ensures that not only cross-sections are treated but also all the side elements, both on the internal and on the external side.

2 of 5The use of welded side rings allows the complete chain to be hardened, including side chains and tightening chains. This results in side elements which are harder compared to standard truck and offroad chains with bent side hooks and they are ready to stand the abuses of heavy duty working conditions.

4 of 5

The central closing hook ensures the cross-sections not leaving any no-chain area in order to reach superior performances, increased stability and a way better driving comfort.

1 of 3Alternation of horizontal and vertical links: this is what the simple link configuration is about.

Vertical links are the ones working more versus the ground while horizontal links act mainly as conjunction between the vertical ones.

The simple link technology is the most gentle while generating a limited vibration level and being the lighest available.

2 of 3The cross-sections are designed to provide the perfect balance between performance and stability which are key for forklifts moving on slippery surfaces.

3 of 3

The use of welded side rings allows the complete chain to be hardened, including side chains. This results in side elements which are harder compared to standard truck and offroad chains with bent side hooks and they are ready to stand the abuses of heavy duty working conditions.

1 of 3The inner hook is the connection point of the inner side of the chain.

2 of 3Welded side rings are the most heavy duty side connections for snow chains involved into demanding Professional activities. The rings are welded in place and, after that, the complete snow chain is subject to a case-hardening process which ensures that not only cross-sections are treated but also all the side elements, both on the internal and on the external side.

3 of 3