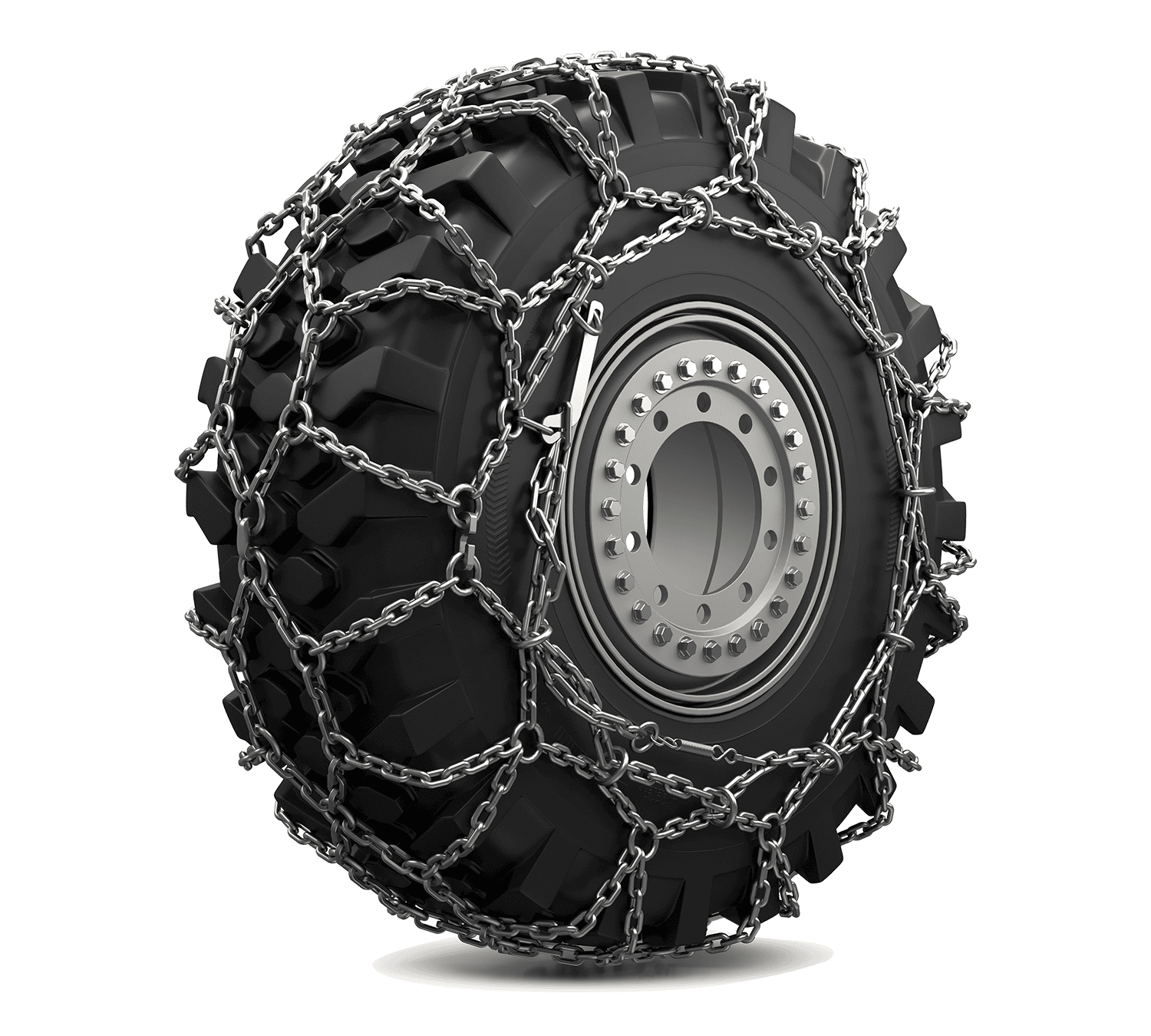

The König DR Light follows completely traces the design language of the König DR in terms of cross-section design, wire diameters and construction.

At the same time, the König DR Light differs for the simple link technology: in fact the König DR Light follows a simple link configuration lacking the ice-breakers and resulting in a lighter and less aggressive chain profile.

The König DR Light is a supplementary grip device certified according to Ö-Norm V5119 thus fulfilling any winter equipment legal requirement.

The product is built following the traditional Professional snow chains construction, meaning that the chain is 100% manufactured in Steel, lacking of any plastic component, cable arch or anything else. Just superior quality steel and the most advanced treatments, plain and simple.

1 of 5Welded side rings are the most heavy duty side connections for snow chains involved into demanding Professional activities. The rings are welded in place and, after that, the complete snow chain is subject to a case-hardening process which ensures that not only cross-sections are treated but also all the side elements, both on the internal and on the external side.

3 of 5The use of welded side rings allows the complete chain to be hardened, including side chains and tightening chains. This results in side elements which are harder compared to standard truck and offroad chains with bent side hooks and they are ready to stand the abuses of heavy duty working conditions.

4 of 5

The central closing hook ensures the cross-sections not leaving any no-chain area in order to reach superior performances, increased stability and a way better driving comfort.

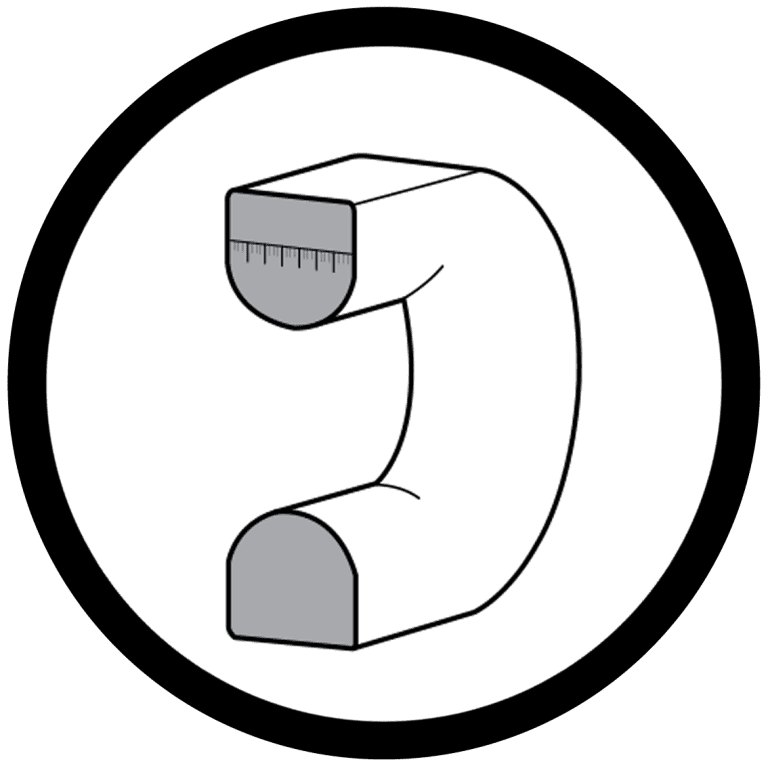

1 of 4Alternation of horizontal and vertical links: this is what the simple link configuration is about.

Vertical links are the ones working more versus the ground while horizontal links act mainly as conjunction between the vertical ones.

The simple link technology is the most gentle while generating a limited vibration level and being the lighest available.

2 of 4The cross-section design is generated starting from two single diamonds getting horizontally flanked and then put in sequence.. This is most typical cross-section design for snow removal chains where the requested traction and resistance level is way higher compared to the typical offroad and truck snow chains cross-sections.

3 of 4

The use of welded side rings allows the complete chain to be hardened, including side chains. This results in side elements which are harder compared to standard truck and offroad chains with bent side hooks and they are ready to stand the abuses of heavy duty working conditions.

1 of 4The inner hook is the connection point of the inner side of the chain.

2 of 4The inner side chain features two or more shackles which are meant to adjust the lenght of the inner side chain, allowing a precise fit on different tyre sizes thanks to a wide adaptability.

3 of 4Welded side rings are the most heavy duty side connections for snow chains involved into demanding Professional activities. The rings are welded in place and, after that, the complete snow chain is subject to a case-hardening process which ensures that not only cross-sections are treated but also all the side elements, both on the internal and on the external side.

4 of 4

The König DR Light represents the ligher and more gentle version of the DR providing a great balance between grip and flow.

It carries all the features needed to run safe and reliable snow clearing operations with a wide variety of machines such as trucks, wheel loaders, tractors and skid steers.

To guarantee a proper application on such vehicle types, the König DR Light is available with different wires (from 5.50mm up to 10.00mm)

Ö-Norm V5119 approved